The patented REV technology in Canada is a new technology developed as an alternative to existing drying technologies worldwide. The vacuum in the system reduces the evaporation temperature of the water and allows the products to be dried at low temperature and in a short time. Products begin to dry from the center to the surface with microwave energy, and as a result of this technology, which is formed by the combination of vacuum and microwave energy, homogenously dried products with preserved nutritional value, color and aroma are created. Due to the low drying temperature, the vitamins, minerals and nutritional values of the products are largely preserved, and products with very high nutritional values are obtained with other methods compared to dried fruits and vegetables.

Our patented vacuum microwave technology (REV) provides homogeneous drying with flexible moisture content that cannot be achieved with Freeze Dry or Air Dry.

NutraREV

Basket type Drying

The raw material is loaded onto the baskets and passed through the vacuum microwave tunnel on the rotating drums and brought to the desired humidity level homogeneously.

-

nutraREV® is suitable for dehydration of organic substances that can be rolled without breaking different vegetable and fruit pieces.

-

Many fruits, vegetables, meat products, dairy products, spices, herbs and grains can be dried efficiently and homogeneously on the nutraREV® platform.

-

NutraREV® machines on a commercial scale are currently used to produce dried fruits, vegetables, dairy products and spices.

-

It can change the combination of vacuum and radiant energy through the integrated HMI and PLC system to achieve the desired end product properties during production.

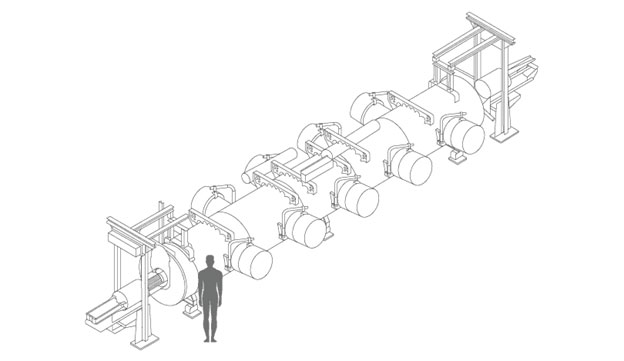

100 kW NutraREV

Application: Large-scale, chain dryer

Microwave Power: 100 kW

Frequency: 2450 MHz

Vacuum: 25-300 Torr

Footprint: 15.3 x 3.8 x 4.6 m (LWH)

Capacity: 91 kg / hr water removal

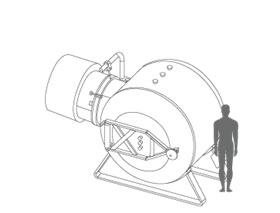

10 kW NutraREV

Usage area: Marketing and R&D trials, test, small scale productions.

Microwave Power: 10 kW

Frequency: 2450 MHz

Vacuum: 12-300 Torr

Footprint: 2.4 x 1.8 x 3.1 m (LWH)

Capacity: 9.1 kg / hour water removal